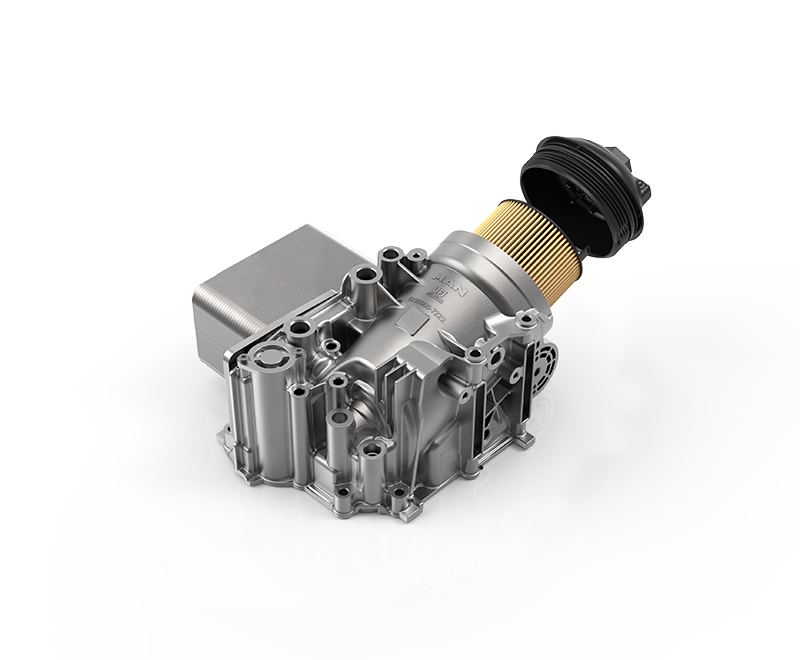

- The first oil module with an aluminium heat exchanger for heavy duty engines, 100% made by UFI Filters

- Advanced thermal management of the lubrication circuit, thanks to the two-stage thermostat valve

- Easy maintenance and replacement of the 100% green cartridge

UFI Filters, a leader in filtration and thermal management, has launched an original equipment oil module for the innovative MAN D15 engine used on many of the German manufacturer’s heavy vehicles. The new lighter, quieter and cleaner engine can be integrated with MAN EfficientHybrid, the intelligent energy and start-up management system that achieves a reduction of up to 16% in fuel consumption and emissions.

The oil module for MAN is the first on the market to feature an aluminium heat exchanger for heavy duty engines; and is vacuum brazed and manufactured entirely by UFI in its new Opole plant in Poland. This customised production process guarantees optimum levels of cleanliness, robustness and reliability. The project marks a further step in the Group’s development of tailor-made technologies for its customers, to meet the strict Euro 6d anti-pollution regulations.

The complete UFI system offers advanced thermal management of the engine, thanks to an optimised heat exchanger that avoids temperature peaks. Depending on the oil temperature and the operating phase (warm-up or full speed), the 2-stage thermostat valve manages the volume of the oil inside the lubrication circuit. The UFI module therefore ensures the best engine operating conditions and reliability, which in turn means lower fuel consumption.

The UFI filter with plastic cap also helps to reduce the weight of the MAN D15 (9 litres), which is 20% lighter than the previous version and available with a power level of 280, 330 or 360 hp. This can be considered a real shift towards ‘downsizing’ in engines of this size – which have shrunk by 12% in height and 10% in width – and UFI’s model has kept up with these changes, offering the best, 50% finer filtering results, down to 17 microns. The environmentally friendly, fully recyclable cartridge uses a specific filter medium and is fitted with plastic stop caps, guaranteeing optimum resistance in the oil circuits of heavy duty engines, which are subjected to pressure levels up to 12 bar.

In addition, the UFI module offers advantages for the Aftermarket sector, where the spare part will be made available within the next six months. The D15 engine is designed to ensure easy mechanic access to the various service points, and to reduce the frequency of oil filter replacement; in fact, thanks to the UFI filtering medium, the filter optimises the life cycle of the engine and protects it from premature wear. UFI recommends that the gasket (supplied with the spare part) is also replaced when replacing the cartridge.

Luca Betti, UFI Group Aftermarket Business Unit Director, says: “Thanks to our R&D investments, backed up by the opening of new industrial sites, we can consider ourselves as global suppliers of management solutions for the complete lubrication system, in terms of both filtration and thermal management. This partnership with MAN, of which we are very proud of, is the best prove that UFI Filters is chosen by the leading manufacturers of heavy vehicles.”